Our Capabilities

Research and Development

Engineering and Certification

First Article Production

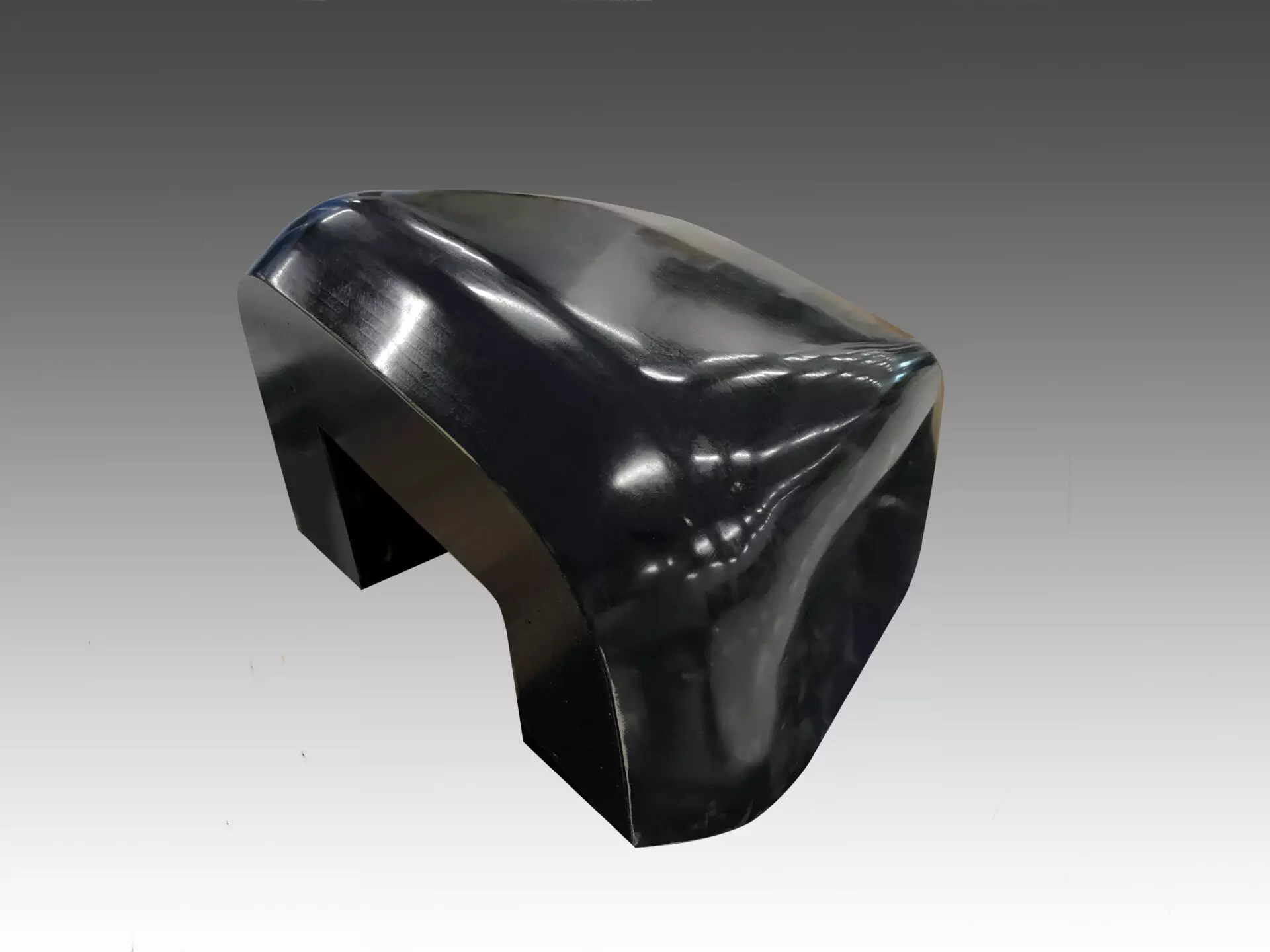

Timeless Materials Modern Methods

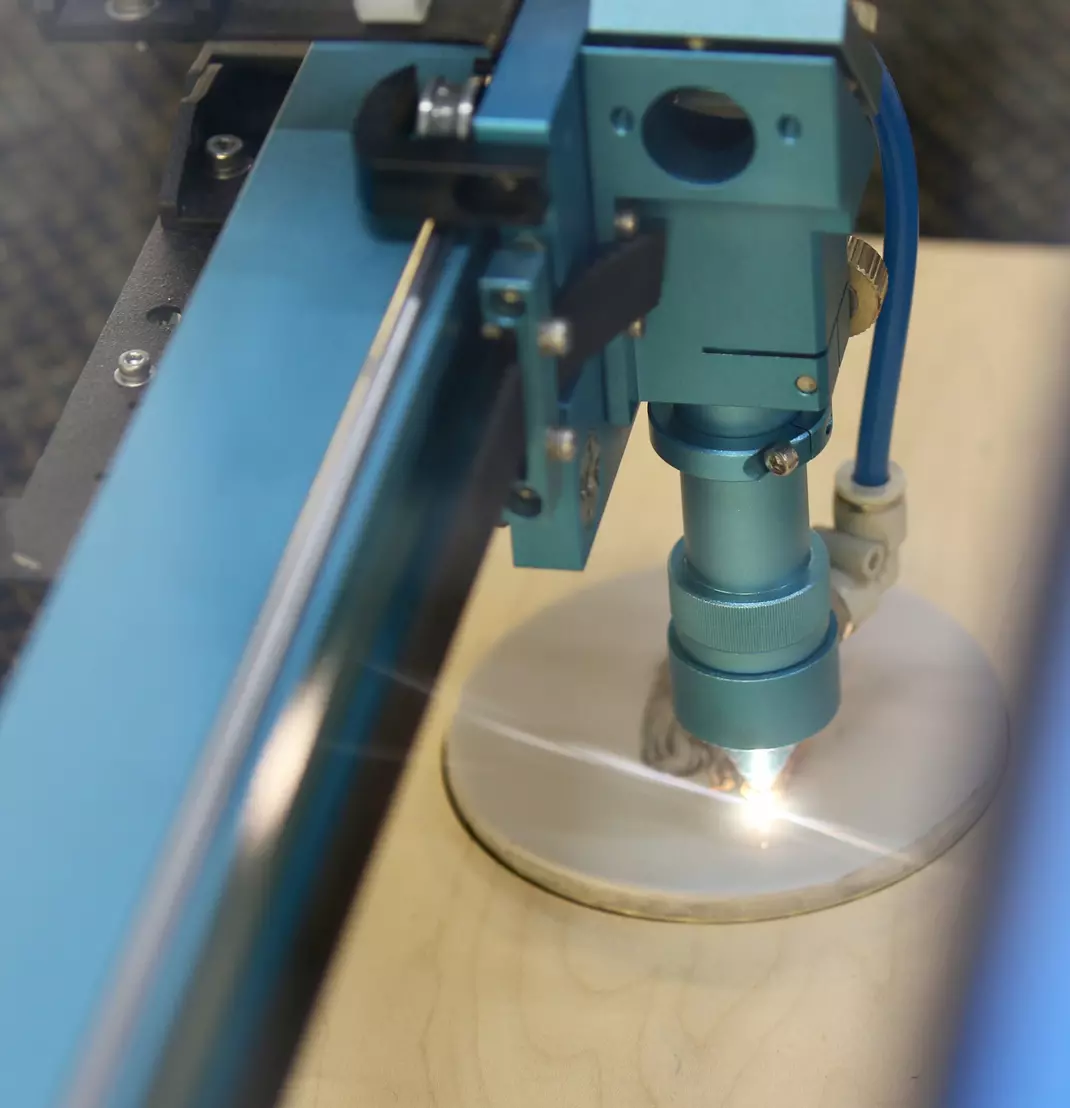

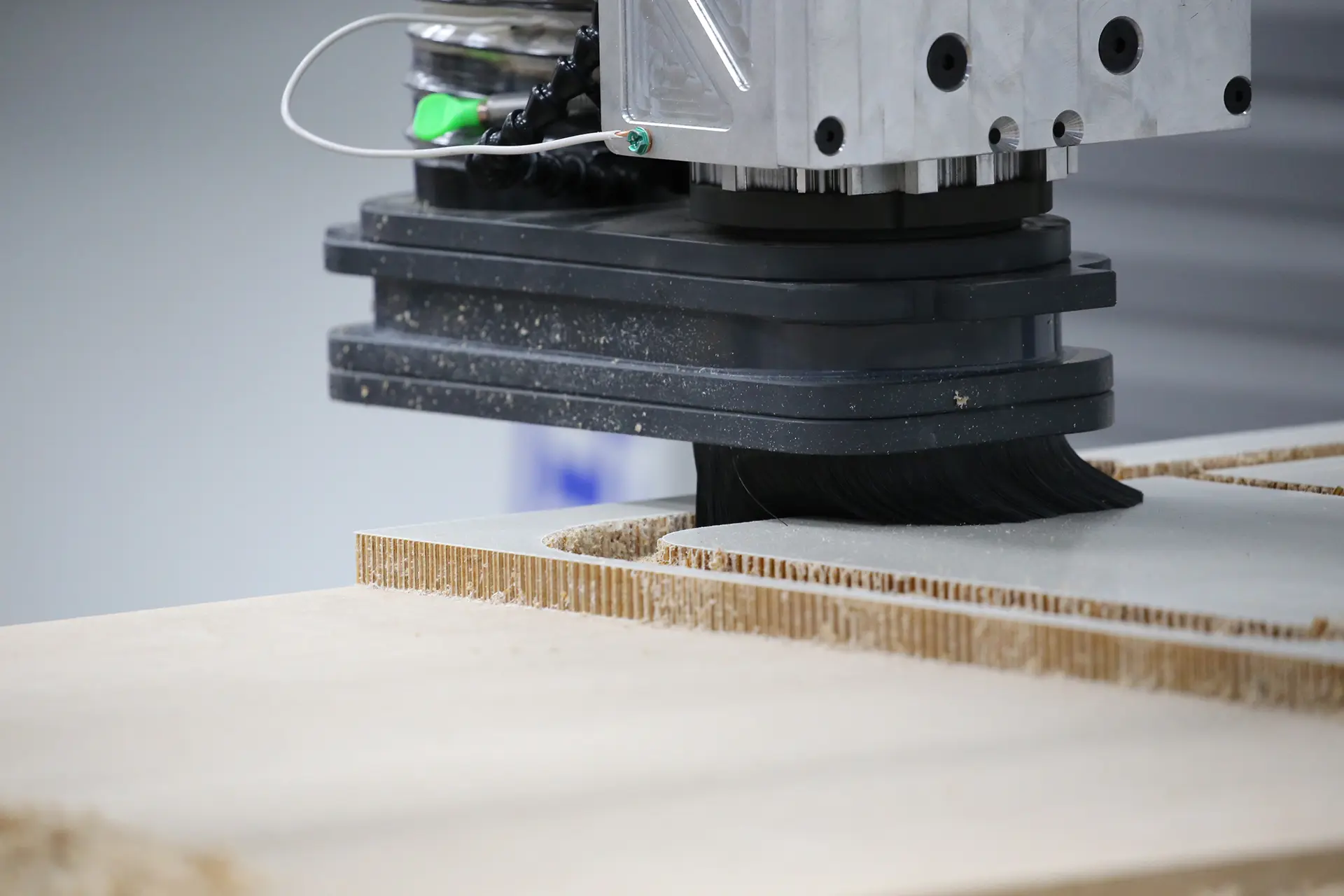

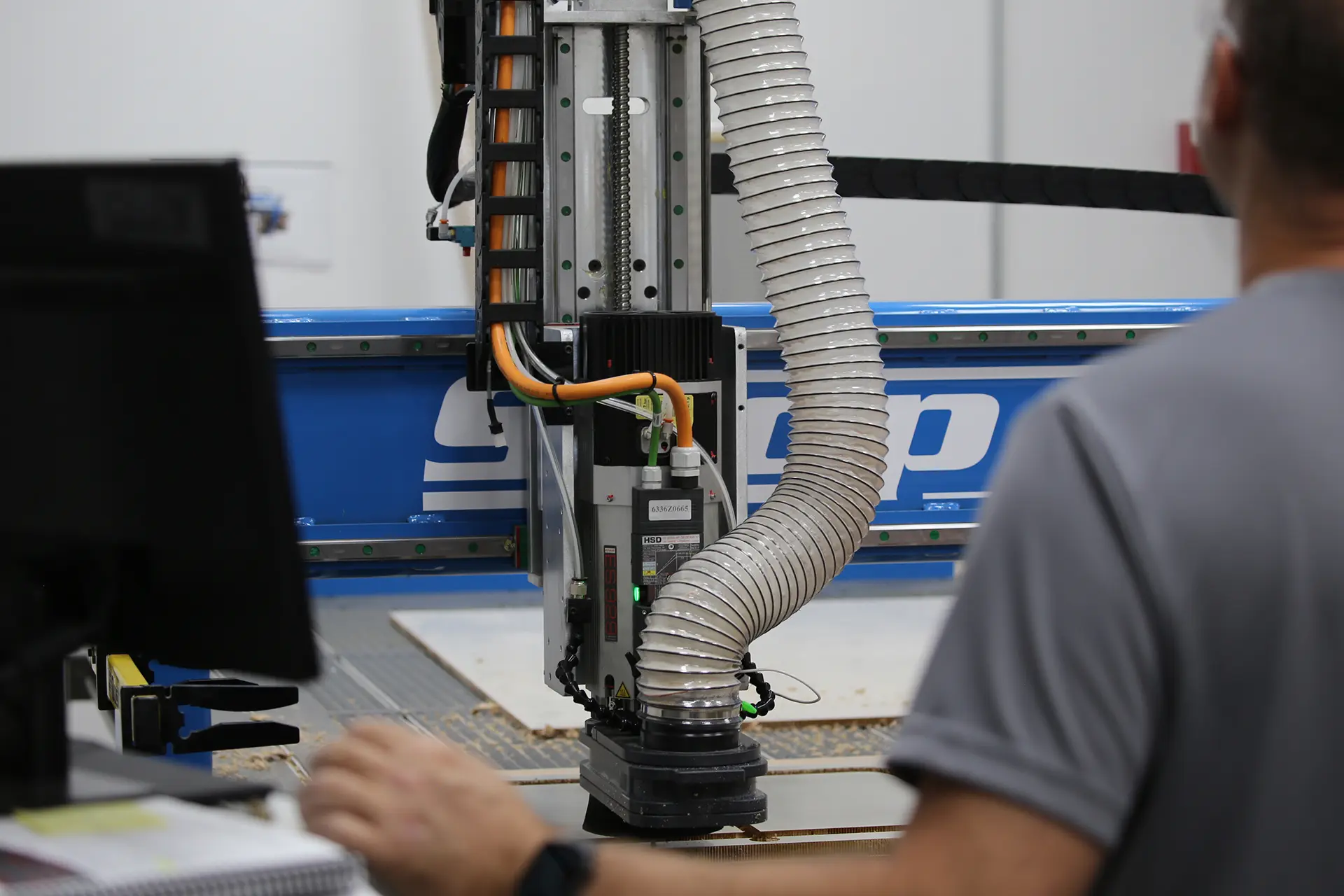

The tools and the know how

Bomhoff Limited can work from your specifications or start from scratch. In addition to traditional drafting and prototyping methods, we utilize the latest in 3D modeling to see the product and make edits before the first cut.

While our list of equipment is always changing, our facility is always equipped with the following:

Full size paint booth

Composite shop

Clean room

Office with advanced connectivity & video conferencing abilities

Metal fabrication shop

5×10 CNC Router

upholstery area

Haas Machining Center

r&d lab

Laser Cutter

Full woodworking and veneer shop

Strategic Partners

In addition to our in-house abilities, Bomhoff Limited has strategic partners with experience across multiple fields. They include firms capable of:

-

Award winning design work including the use of AR/VR and the creation advanced 3D renderings

- 3D printing for prototyping and production work

- Precision custom metal work

- Design and fabrication of large structural composite parts

Their renowned handiwork can be found across diverse industries, and they share our commitment to excellence and interest in innovation. Know that when you hire us, you’re hiring more than just an aviation contractor, you’re retaining a full suite of capabilities.

Facility

Bomhoff’s state-of-the-art facility has everything an advanced interior component manufacturer would need. The facility is built with versatility in mind, allowing different spaces to be quickly reconfigured depending on project specifications. As a former cash vault for a national bank, its sturdiness and advanced security provide an ideal environment for any proprietary work.

Located just 3 minutes from Tucson International Airport, including Tucson Executive Terminal and the Million Air FBO, it provides easy access to airport accommodations, or one of Tucson’s many sunny resorts.